Isle firm plans

new facility for

irradiation

A company official promotes its

potential for agriculture exports

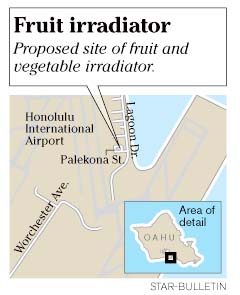

A Hawaii company plans to build a commercial irradiation facility near Honolulu Airport to treat Hawaii fruits and vegetables for export.

Pa'ina Hawaii submitted an application to operate a "underwater pool-type commercial irradiator" to the U.S. Nuclear Regulatory Commission on June 27.

Pa'ina President Michael Kohn said he hopes to have the facility in operation by February 2006 and that it will have the potential "to treat 80 million pounds of papaya per year."

Pa'ina President Michael Kohn said he hopes to have the facility in operation by February 2006 and that it will have the potential "to treat 80 million pounds of papaya per year."

But at the outset, the facility's first customer might be Kohn's own Hawaii Fruit Co. "I will be a customer, but this is not an irradiator for Michael Kohn, but for Hawaii agriculture," Kohn said.

"You can irradiate any agricultural products in it -- tomatoes, cucumbers, bell peppers, anything hollow that can host a fruit-fly larvae," Kohn said.

Kohn said he used to be skeptical of irradiating food with radioactive materials to kill bacteria and insect pests but has been convinced that it is safe and effective.

Lyle Wong, administrator of the state Department of Agriculture's Plant Industry Division, said the project has the potential to open up new export markets for Hawaii produce that have quarantine restrictions on it because Hawaii has fruit flies.

The facility also could be used for programs that sterilize male fruit flies for export to the mainland, where they breed with wild female flies, producing sterile eggs and helping reduce fruit-fly populations, Wong said.

And it could be used to treat incoming flowers, some of which bring insect pests into Hawaii, Wong said.

Wong said he supports irradiating Hawaii produce as a means of getting it into the mainland market.

Hawaii's only existing irradiation facility is in Hilo, and it's cost prohibitive for Oahu, Maui and Kauai growers to ship produce there for treatment, Wong said.

Henry Curtis, president of the Life of the Land environmental group, said he wants to learn more about the facility.

"My concern is how the irradiation affects the food itself," Curtis said. "While it may not leave any radiation on the food, I'm not sure if it affects the nutritional value or if toxics might be produced. We'd certainly look at the application very carefully."

Kathy Dorn, a Big Island resident who opposed proposals to put an irradiation unit there, said, "We opposed it because we were opposed to the importation of radioactive materials."

Dorn advised Oahu residents "to look very carefully into this and see what they're talking about. Realize accidents happen. Toxic products could damage the image of the Hawaiian fruit as being healthy and wholesome."

Pa'ina plans to use a Graystar Genesis irradiation unit, which keeps Cobalt-60 in a 20-foot deep pool of water, which shields it from human contact, Kohn said.

About 600 pounds of items to be treated are loaded onto pallets that are covered with stainless-steel "bells" that resemble diving bells. These are lowered into the water with pressurized air inside the bell so the items don't get wet, and held over the radioactive material for several minutes.

He said his unit will fall well below the federal Food and Drug Administration maximum radiation level for food irradiation. The commission will hold a public meeting on the application within 60 days, it said in a news release yesterday. Notice of the meeting will be announced on the Nuclear Regulatory Commission's Web site at www.nrc.gov.

The irradiation unit can be seen at: www.graystarinc.com/genesis.html

|

E-mail to City Desk

[News] [Business] [Features] [Sports] [Editorial] [Do It Electric!]

[Classified Ads] [Search] [Subscribe] [Info] [Letter to Editor]

[Feedback]