SOME BUSINESSMEN and inventors in Pearl City are busy tweaking what they believe will be a fabulous product. And it may be. Trouble is, they don't know what to call it yet.

But stronger, lighter,

cheaper and made with

recycled fibersBy Burl Burlingame

Star-BulletinTBN Building Products is cranking out a decorative rock material made of recycled trash. It not only is a dead ringer for dozens of rock and stone veneers, it's lighter, stronger, easier to work with and cheaper. It just doesn't have a name hung on it yet.

Director Bob Pecel shrugs. He knows they need a catchy trademark in these marketing-savvy times. "TBN?" he laughs. "We just picked the letters out of the air. It means nothing, or anything you want it to. Transpacific Burl Nancy. How's that?"

How about Rock-On? Or, Fakerock? Everybody Must Get Stoned? Ziprock? Bricks 'R' Us? Shale University? Betty Rubble's? Any bright ideas, call 'em at 454-1430.

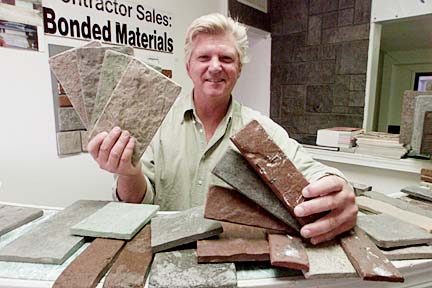

In the meantime, they're busy getting the product, whatever it'll be called, into stores. It's already available for contracting pros through Bonded Materials on Puuhale, and will soon be available through neighborhood home-improvement outlets such as City Mill and Ace. If you want some right away, Pecel or associate Moses Magno will be happy to sell you some at the Pearl City Industrial Park plant, D-6, 95-1186 Waihona.

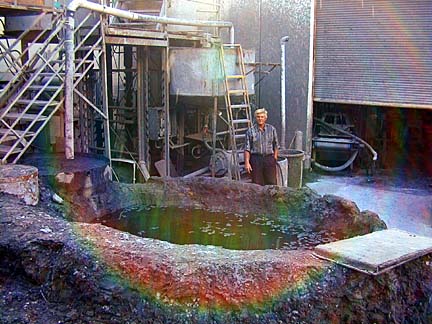

But what are you getting? Out back of the plant is what appears to be a rock-hard papier-mache volcano, inside are samples and stacks of prepped rock faces on pallets.The material and the manufacturing process are trade secrets, but the result can safely be described as a space-age composite material, a kind of super-duper papier-mache that's waterproof, fire-proof and immensely strong.

"They're all organic in origin," said Pecel. "The primary material is organic fiber, though. You can get that from almost anywhere -- yard clippings, trash, coconut husks, cardboard boxes. But what we use almost exclusively is recycled newsprint."

He smiled. "Thanks to this two-newspaper war you've got going on, we have plenty of scrap newsprint available these days!"

The material is shredded and broken down with chemicals -- similar to the way living creatures digest food -- mineralized and colored and super-compressed into big patties.

TBN winds up with a material that looks and acts like stone, without stone's fragility, weight and cost. "We say that it's 10 times stronger than stone, but it's not," said Pecel, urging the reporter to whack a sample with hammer. "It's actually nearly 30 times stronger."

Mighty whacks on what appeared to be a piece of shale didn't even dent it. But the same stuff can be cut with a table saw, filed, sanded or even nailed."No matter how long it was left in a fire, it didn't catch. Compressability is real good too, about 6,000 pounds. We put some on the cement truck scales at Hawaii Cement in Halawa, and gave up trying to ruin it after 868 millions tons of cement trucks rolled across it."

Although an additional five plants are being constructed across the United States, the TBN product is a homegrown Hawaii invention. Its primary uses are as paving stones and building veneers, although there's no reason it couldn't be used as indoor decoration. The primary sizes cut from the sheets of material are paver-sized.

Joe Wasco of Kaneohe took a chance on a preliminary version of the product last summer and treated himself to a "slate" driveway. "It's held up amazingly well," said Wasco. "Water runs right off it, cars and trucks are always on it, yet it's comfortable to sit on."It installs with mastic or thin-set cement, with standard-issue grout placed in the joints. TBN has a videotape with instructions available. Ironically, if placed atop an asphalt driveway, it adheres better to older, rougher asphalt than blacktops that are well preserved.

Real rock will run you about $5 a square foot. Pecel estimates his product will run about $3 a square foot, and that includes other materials and labor.

"And it's a 10th of the weight of slate which means that less strain is placed on a building, and it's easier to use it upstairs," said Pecel, leaning against a pallet filled with blocks. A pallet-full weighs about 1,200 pounds, vs. several tons for a rock-loaded pallet. It comes in a variety of thicknesses, with the thickest being 1-inch pavers. They can make it up to 2 inches thick, if necessary.In most cases, the color is mixed throughout the material. Some examples, such as distressed bricks, require additional painted surfaces. You can even special-order certain shades -- "greens are the hardest" -- although Pecel points out that it's the variety of shades that makes the material look natural.

And they're busy at the moment trying to nail down a realistic coral finish for the Hawaii market. "It's not just a matter of little holes in the surface," said Pecel. "Coral has a unique texture and feel and color."

Does Pecel find himself looking at rocks more closely these days?

He laughed. "No kidding! I'm often down on my hands and knees, looking at rock walls like they're great works of art. It's the attention to detail and realism that makes the product so cool."

Whatever the product's called.

Click for online

calendars and events.