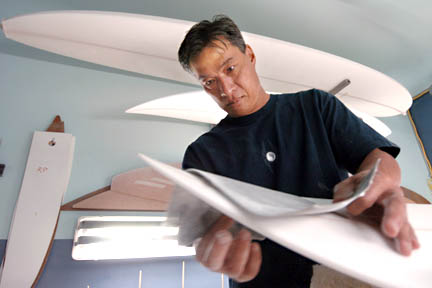

Glenn Pang shapes as many as 2,000 surfboards a year, mostly for Town & Country Surf Shop. He uses computer equipment to design the boards, has them rough cut elsewhere, then finishes them with hand sanding tools. Pang, sands the ridges of a rough-shaped board to a smooth exterior.

Shaper of things

to come

Glenn Pang loves to surf, and he loves to make surfboards for others who love to surf. He started making them as a kid, and now makes about 2,000 a year as a professional for Town & Country Surf Shop, which has outlets throughout Hawaii, including a factory in Campbell Industrial Park and sells surfboards worldwide. Pang, 47, is a 1975 graduate of Leileihua High School. He is married ("just made 20 years") to the former Karen Hirai, whom he met while taking classes at the University of Hawaii. The couple lives with their three dogs in Wahiawa.

|

Who: Glenn Pang

Title: Surfboard shaper Job: Designs and applies finishing shaping touches on surfboards

|

Answer: From the '70s -- actually the early '70s. I kind of just started in my garage, doing boards for friends and my brothers, and it just grew from there.

Q: Who taught you?

A: I'm kind of just self-taught. I had a friend's brother I saw make a board, and I kind of thought I'd just go and try it, and it went from there.

Q: How long have you been working for Town & Country?

A: I'm a contracted worker for them. I was with them for the first time in the early '80s, then did my own thing for a while -- worked for other companies -- then I've been back with them for about 10 years, I guess.

Q: How many boards do you make a year?

A: Probably about 2,000 boards a year.

Q: How many boards do you think you've made overall during your career?

A: Oooh, I wouldn't even know.

Q What's your typical day like?

A: Get up in the morning, go on the computer, see how the waves are, listen to the surf report. If it looks good and I have time, go for a surf. If not, if the waves are dead, or there's too much work to be done, watch the news in the morning, then head to the shaping room, which is just downstairs, and then get done what needs to be done.

A: I try to get done by the half point in the day, then go down to the Town & Country factory (in Campbell Industrial Park) and drop off all the blanks that I shaped.

I design all the boards with a CAD system -- everything is on computer. So we put the designs on floppy disks and take them down to T&C, which has a shaping machine at the factory. So whatever I design on the computer is cut for me at the factory. Then they give me the shaped blanks back, I bring them home and finish them off here. Their shaping machine saves me, like, 75 percent of the work. The other 25 percent is mainly fine-tuning the board -- putting the fine details on the board.

Q: Do you paint them too?

A: No, I don't. We actually have an airbrusher at Town & Country that sprays all our boards. My job is pretty much designing and shaping the boards, and the rest is done at the factory.

I also work with the team riders. I give them boards to ride, and they tell me what they like and don't like, and then we make adjustments to the boards. We can change the width of the board, the concave of the board, the rockers; whatever we want, we can change on the CAD system to make the next boards better.

A: Is it dangerous work in any way?

Q: Before it was, because you used power tools, but now it's more a thinking job, 'cause you're always trying to make a better board, and what you need to do is figure out a way to improve on that board.

Q: What's your favorite part of making a surfboard?

A: Actually, probably riding, trying out a board. (Laughter) There's nothing like riding your own board. Guys can tell you what it feels like to them, but until you ride it yourself, it's hard to tell what it's actually doing.

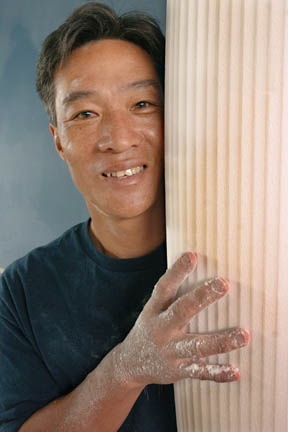

Glenn Pang, with dust from a foam surfboard blank fresh on his hands, works out of his home and workshop in Wahiawa. His favorite kind of boards to shape are short boards or guns; his favorite part of the job is trying out his creations in the waves.

A: My specialty is mainly short boards and guns (big wave boards). I do a few long boards a year, but not too many -- just a few for friends.

Q: Have you been inspired by any other shapers?

A: Well earlier there were guys like Dick Brewer and Ben Aipa. They were probably the two hot Hawaiian shapers at that time.

Q: What about today?

A: There's so many good shapers now. The most well known and respected shaper would probably be Al Merrick, from California.

Q: Do people ever confuse you with surfboard shaper Dennis Pang?

A: Yeah. Everybody thinks we're brothers. Both of us shape, both of us used to work for T&C, so they think we're related somehow.

Q: What about those surfboards that are coming out of China, that you can buy at Costco and Sam's Club and places like that?

A: It's kind of hurting everyone, because most of the guys working on those boards probably don't even surf or live near the beach, whereas for most of us guys it's more like a lifestyle. We've been doing it all our lives.

[News] [Business] [Features] [Sports] [Editorial] [Do It Electric!]

[Classified Ads] [Search] [Subscribe] [Info] [Letter to Editor]

[Feedback]