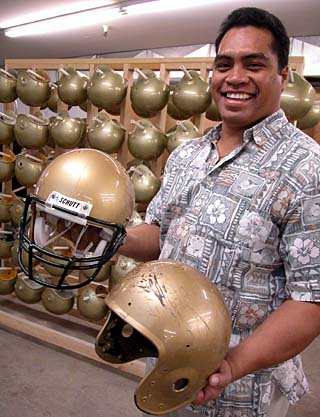

GEORGE F. LEE / GLEE@STARBULLETIN.COM

Marvis Tauala of Maxletics tests the safety of football helmets at the Emily Street business he runs with three partners.

Like new again

Two athletes, a sportscaster and

a safety guru have teamed up to

refurbish Hawaii's football gear

The football helmet slams onto the anvil with a resounding thud.

Another helmet is placed over the aluminum skull shell before powering through the 5-foot-drop in less than a second.

Thud.

Each time, the severity of impact is recorded by an electronic testing device to determine whether the helmet falls within the range of concussion tolerance.

Maxletics

Address: 729C Emily St., Honolulu

Telephone: 597-8660

Employees: 11

Founded: 2002

Notable: One of 33 companies nationwide -- the only one in Hawaii -- with national certification to recertify football helmets.

For Maxletics, a 1-year-old company that reconditions and recertifies football equipment in downtown Honolulu, football is a 365-days-a-year business. It is one of 33 companies nationwide -- and the only one in Hawaii -- with national certification to recertify helmets. And it has a big selling point over its mainland competitors -- no shipping charges.

"This is your kids' safety on the line," said Chief Financial Officer Kelly McGill, who was approached with the idea three years ago by President Marvis Tauala, a former football teammate of McGill at the University of Hawaii.

"Marv and I actually had the opportunity to coach together (at Kaimuki High School), so we've been through the process on the other side of the fence and have gone through some of the heartaches that these coaches go through getting stuff off to the mainland," McGill added. "That was part of the reason why we wanted to start this business."

Chief Operating Officer Kelly Herauf, a registered nurse with a background in occupational health and safety; and UH football and basketball announcer Bobby Curran, the director of sales and marketing, make up the rest of the partnership team.

In addition to the four partners, Maxletics has seven part-time employees, consisting of a seamstress and six others who clean and repair equipment.

Maxletics, which kicked off its business on Dec. 1, 2002, now services 65 percent of the state's 46 high schools, as well as some of the 80 youth football teams and the arenafootball2 Hawaiian Islanders. The company also hopes to do all of the UH football team's equipment this year after doing only the Warriors' shoulder pads last year.

That's quick growth for a company that serviced just 12 percent of the state's football equipment market after the 2002 football season.

"We wanted to open a facility over here that could keep the coaches, parents and administrators in the process," McGill said. "At the same time, because of state budget cuts, we also wanted to offer them an alternative to save a little money from what they were spending on shipping alone."

Maxletics' playing field is a downtown Honolulu warehouse, just a long pass from Lex Brodie's Tire Co.

Helmets and shoulder pads hang from movable racks. Laundry bags are piled up in the corner. Worktables occupy the front of the room while industrial-strength washers and dryers are lined up in the back.

GEORGE F. LEE / GLEE@STARBULLETIN.COM

Maxletics is headed by, from left, Marvis Tauala, Bobby Curran, Kelly McGill and Kelly Herauf.

Stacks of boxes containing incoming and outgoing equipment are scattered around the room.

Curran, who hosts a daily morning radio sports talk show on KKEA 1420 AM, said that before he joined the venture he had planned to contribute public service announcements because he thought "it was a win-win situation for (the company) and for the island."

But following a chance dinner conversation with McGill, Curran decided to enter the game and become a partner in Maxletics. He said beginning his Hawaii broadcast career doing football games made him aware of the financial crunch facing prep football programs.

"I still feel that even if we end up breaking even, well, I'll live with that because you feel like you're getting the chance to do some good," said Curran, who has been working in sports in Honolulu since moving to Hawaii in 1983. "If one kid is saved from a broken neck because we fixed their helmet, you feel good about it."

The partners are all linked by association. Tauala played defensive tackle for UH from 1993 to 1995 and in practice often opposed McGill, who was on the offensive line from 1990 to 1995. Curran was on the broadcast team for their games while the other partner, Herauf, is McGill's uncle.

Tauala, who doubles as a union agent for the Hawaii Government Employees Association, said he came up with the idea for the company when he was coaching at Kaimuki and discovered there was a need for the reconditioning of football equipment.

"There are a lot of people out there who wanted to do it but never took the step further to get it up and running," Tauala said.

One of Maxletics' first customers was Farrington High Athletic Director Harold Tanaka, who had been Tauala's football coach at Kaimuki High School. Tanaka had spent $2,700 on shipping Farrington's football gear to the mainland in 2001 and $2,000 in 2002. Last year, he spent nothing on shipping costs after switching his allegiance to Maxletics from Elyria, Ohio-based sports equipment company Riddell.

CRAIG T. KOJIMA / CKOJIMA@STARBULLETIN.COM

Maxletics partner Marvis Tauala holds a beat-up helmet, at right, and a cleaned-up one at left.

"I'm really happy with the work we've been getting from Maxletics," Tanaka said. "Our athletic monies have been decreasing year after year, but with the money we saved by having it done locally, we were able to turn around and get extra equipment from Riddell. It's crazy not to have it done here."

Tauala said football helmets can last from one to 10 years depending on the amount of contact they endure. On average, he said, they last three or four years. The National Operating Committee on Standards for Athletic Equipment recommends that helmets be certified annually to meet safety standards.

Not all youth leagues, however, have adhered to the annual helmet recertifications. Tauala said Maxletics has seen helmets and other equipment come in that have been jury-rigged to remain functional.

"There are standard pads that go in a specific helmet," Tauala said. "We have helmets coming in where we have socks in them (to get a better fit). You'll find erasers in shoulder pads (to raise the pads to a higher level). Some people put a deck of cards in the front side of a helmet to absorb some of the impact. So you've got a lot of unsafe equipment out there."

In addition, Tauala said, helmet pads sometimes are not the right size, are worn, or have hardened over time.

Curran said it's been a battle to get the message through to the youth leagues.

"We are doing anybody we can get a hold of and convince to do it," Curran said. "I'm really concerned about the youth leagues because some of them, frankly, don't recondition. They take terrific risks. They don't have a lot of money to work with and sometimes corners are cut -- not because they want to but because they have limited resources.

"The enforcement is not good at the youth league level. So it really takes a commitment on the part of the coaches and parents that this stuff gets reconditioned."

When Maxletics receives a team's helmets, they are broken down and inspected for any damage or defects. The helmets, and the pads inside them, are then sanitized in high-pressure water. They are then buffed, shined and, if necessary, repainted or given logos before being reassembled.

"If a helmet comes in and needs a full reconditioning, we basically replace everything except the shell," McGill said. "We replace the facemask, the chin straps ... we put it out looking brand new."

Herauf, who spent 23 years as a registered nurse in orthopedics at Kaiser in Santa Clara, Calif., and three years at Intel Corp. in occupational health and safety, inspects all the shoulder pads and repairs them himself. The most typical repair for a shoulder pad involves the strap buckles. Other work includes replacing rusty rivets or rivets that have popped out, and sewing torn pads. All pads are sanitized, as well as given new laces and straps.

Curran describes Maxletics' seamstress as "terrific." He said she's able to make repairs to items that look like they should be thrown out "almost so that you can't notice them." She also puts numbers and names on jerseys.

The uniforms, some of which are stained with red clay, are cleaned in industrial-strength machines.

"We have all these chemicals (for the washer) hooked up," Curran said. "This stuff goes beyond the stuff you see on TV with the mother in the commercial with the detergent. This is the real deal."

Maxletics, which picks up and delivers, can do same-day repairs on equipment during the season for Oahu teams and overnight for neighbor island squads.

"Last year our first customer was the Hawaiian Islanders," McGill said. "We were able to bring them in here and satisfy their needs. On a weekly basis, we did their laundry. We did all their repairs. We even stitched their mascot. We did all the helmet polishing before each game, and that's carried over into this year. That translated into more high schools hearing what kind of work we did."

McGill said the company is not profitable yet, but feels things are moving in the right direction.

"We're getting there," McGill said. "This is really our first season. Last year was kind of a testing ground to see what type of market we could pull in."

Added Curran: "We think that service, not to mention the better quality of work and the lower price, eventually will drive the market to us. It should."