Advertisement - Click to support our sponsors.

Forget about wood and

By Burl Burlingame

make way for the new kid

on the block, Polysteel

Star-BulletinIT was in the planning stages of Bob Wells' new family home on Portlock Road that contractor David Horne made a startling proposal: Skip the traditional wood, metal or stone construction. Make the house out of Styrofoam.

He wasn't kidding. Wells, a San Francisco-and-Hawaii real estate developer, was concerned about metal construction with the building so close to the water, block is expensive and ugly, and wood is termite food, after all. Horne had read about a material called Polysteel, not used before now in the islands.

"It seemed like a very logical system for Hawaii," Wells said.

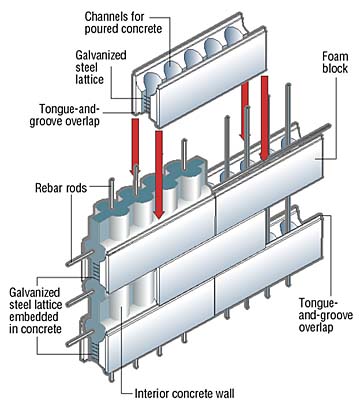

Like all the great building materials, Polysteel is pretty simple stuff. It's essentially a giant hollow Lego block held together with a galvanized-steel lattice. Stack 'em up like toy blocks, fill them with rebar and concrete and the wall is done. Next floor, please."I checked into the product and noticed there was no distributor in Hawaii, so I became one," said Horne. Now there's another house in Kona being built with the stuff, and more on the way, said Horne.

"The only thing that slowed us down was that Polysteel had to send someone from Phoenix to teach our guys how to use the stuff," said Wells.

The blocks are cleverly designed to fit together precisely, with tongue-and-groove overlaps, and the interior spaces are channeled to create the strongest possible wall with the least amount of concrete. A standard foundation is poured, and the first row of Polysteel blocks are glued in a straight line. The rows above stagger the blocks like bricks, which are glued into place with foam glue. Door and window spaces are framed out, and plumbing pipes lie inside the interior channels, along with rebar strengthening rods.

Because of the way concrete sets up inside waterproof spaces (a process called hydration), concrete inside Polysteel hardens with a greater tensile strength than slab concrete.Polysteel walls typically use 25 percent less concrete and are 50 percent stronger than traditional concrete walls.

"I was very influenced by the strength advantages, in case it had to stand up to hurricanes or tsunamis," said Wells. A former architecture student at the University of Hawaii, he designed the house himself.

Electricians lay conduit directly into the foam by cutting it with a hot knife. "The foam is an inch-and-a-half thick, and code calls for an inch-and-a-quarter, so it fits great," said Horne. The metal ends of the lattice double as attachment points for drywall on the building interior; the outside is generally coated with stucco. The Polysteel foam forms are left in place, doubling as both insulation and soundproofing.

How much?

"Depends on the size of the job," said Horne. "It has to be shipped in from the Mainland in a container, and the raw materials price is a bit more than wood. If it were manufactured locally -- and we have people eager to do that if there's a demand -- it would be less than wood."

The crucial differences affecting home construction prices, Horne and company learned, were in labor and speed. Typically, these costs are about 120 percent of the cost of materials. These drop substantially when using Polysteel; work breezes along."Very, very fast," said Well. "Substantially faster than other houses I've built."

"The first floor of the Portlock house was built in five days," said Horne. "Five days! Normally, it would have taken at least three weeks. So labor goes way, way down, and you can do it yourself because there's no heavy lifting. We have a videotape that shows you how to do it and meet code. You can have the professionals do the floors and roof."

Speed and cost aren't Polysteel's only attributes. Besides being strong enough to withstand hurricane damage, it reduces the overall weight of the house and therefore the load on the foundation, it's not tasty to termites, doesn't expand and contract in heat like wood. The resulting house is extremely cool. The Styrofoam becomes an insulation material with about an R-50 energy rating, said Horne.

The Styrofoam also leaves homes very, very quiet. "With double-glazed windows the house is practically soundproofed," said Horne.

"I don't know how quiet it will be!" laughed Wells. "I designed it to have lots of louvers to let the breezes flow through. It's a Hawaii house, after all."

Polysteel is available through Polysteel Hawaii, 235-7775. They have samples and literature available. A shipment takes about three weeks to arrive here. Technical data is available online via the company Website: www.polysteel.com. Curiously, the Website notes the material is "bullet-resistant."

Click for online

calendars and events.